What are the common surface treatment of honeycomb panel?

Aluminum honeycomb panel have wide applications,it can be used for exterior and interior wall cladding,decorations.For different application scenario,there are many commonly used surface treatment for aluminum honeycomb panels.

1. Precoat painting

The pre-coat paint baking roller coating is to coat the aluminum plate flat, and the aluminum plate is placed on the coating production line. All the color packages can be matched against the RAL (Raul) color card, such as wood grain,stone grain can also be perfectly realized.

2. Anodize

Anodizing process is different from ordinary painting process. The aluminum by anodizing has excellent anti-fouling ability. The special structure of the oxide film makes the surface of the curtain wall not adsorb dust and leave fingerprints, which undoubtedly greatly reduces the risk of repair and maintenance for high-rise buildings.

3.Wood veneer

It can be completed only by assembly and combination, thus reducing the site Planing, sawing and other noise and decoration garbage pollution; so as to truly achieve environmental protection, safety, and respect for people and the environment.

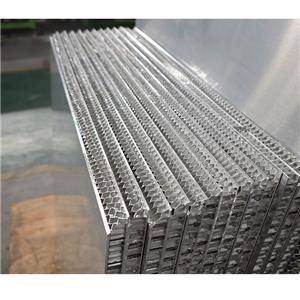

4.Mill finish

Mill finish aluminum is always used for further lamination,or used for internal floating roof.

5.PVC film

PVC film is decorative film on aluminum honeycomb panels,it has rich color and economy,

6.PVDF coating

7.Powd coating

8.Pe coating

Quotation

The aluminum honeycomb panel size is customized by customers, and different application has different size. So before I send the exact FOB&CIF quotation to you, please tell us the panel thickness, application, size(Length*Width), quantity and destination port.If you firstly use our aluminum honeycomb panel materials, please tell us the application and size, we will give you some free advice about panel thickness.