Customized Aluminum Honeycomb Panel Edge Banding Factory

- Huarui

- Foshan,Guangdong

- 5-15days

- 1500㎡/day

● Customized luminum honeycomb, including size, shapes, finishes

● Honeycomb panels have significant benefits led to the widespread application such as architectural decoration, furniture manufacturing, and transportation.

Customized Aluminum Honeycomb Panel Edge Banding Factory

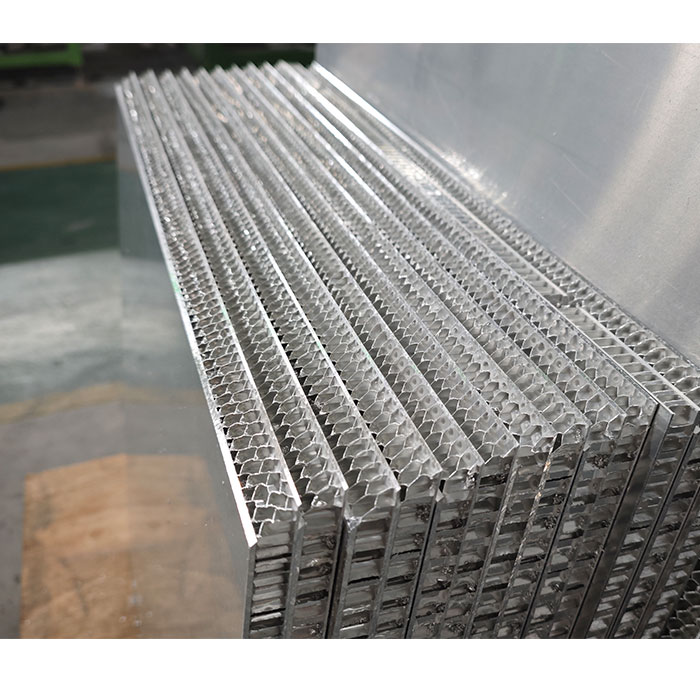

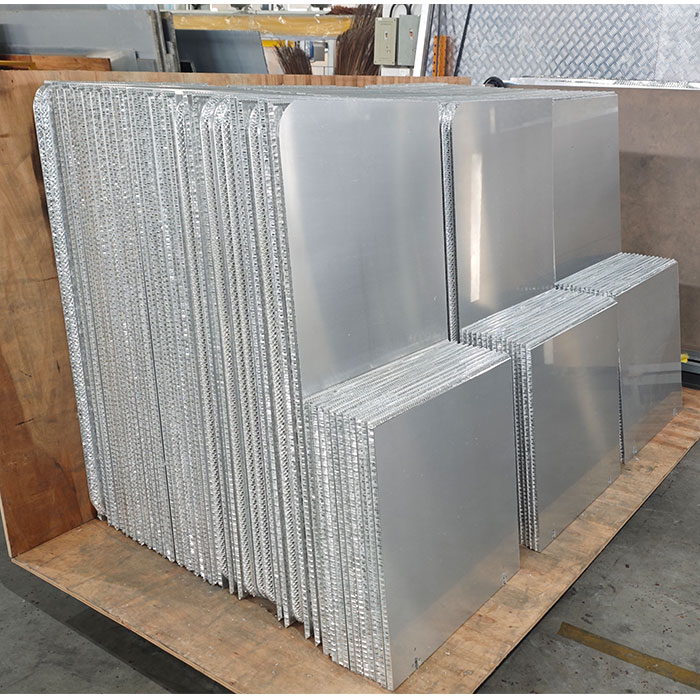

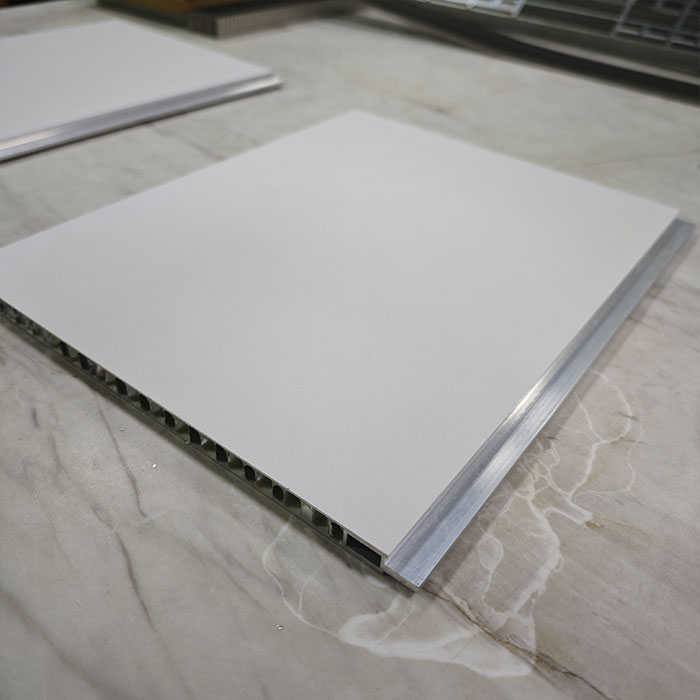

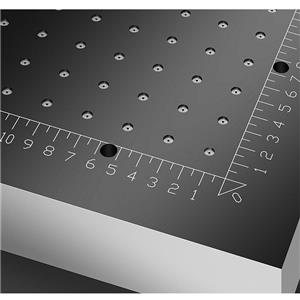

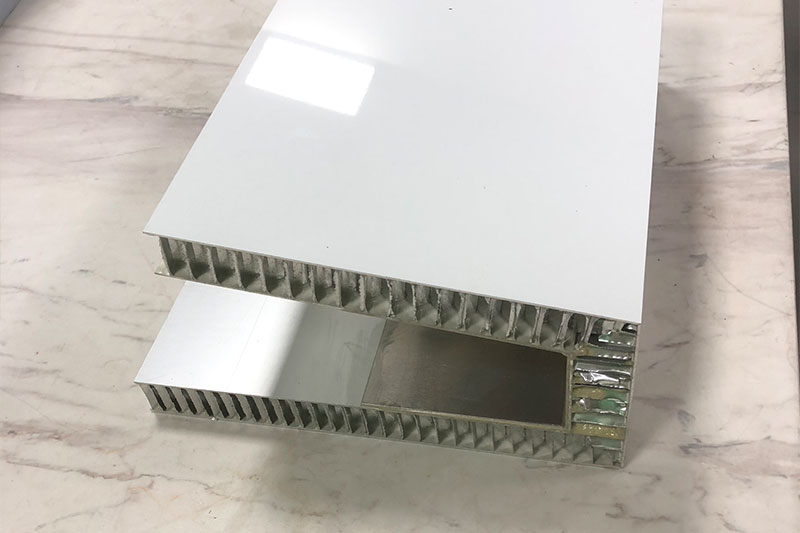

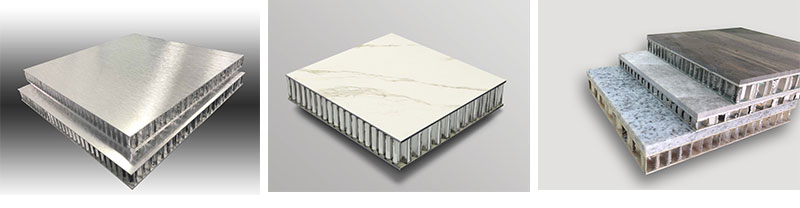

Aluminum honeycomb panel is a lightweight, high-strength, and versatile material, provided solution for applications ranging from architectural facades to industrial equipment. Honeycomb panel edge sealing - This process not only improves aesthetics, but also determines durability, structural integrity, and long-term performance.

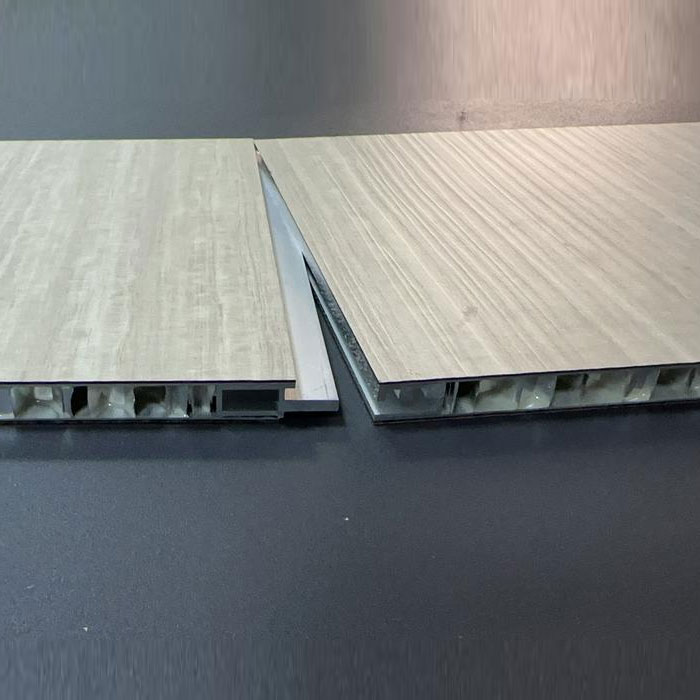

Huarui can perform edge sealing treatment on honeycomb panels according to the actual application needs of the product. In addition to our edge banding services, we also offer a variety of other customizations for aluminum honeycomb panels, including sizing, shapes, finishes, and more.

Specification

| Size | Customize | |

| Standard thickness | 10mm,15mm,20mm,30mm | |

| Min/Max thicknes | 3mm/ 500mm | |

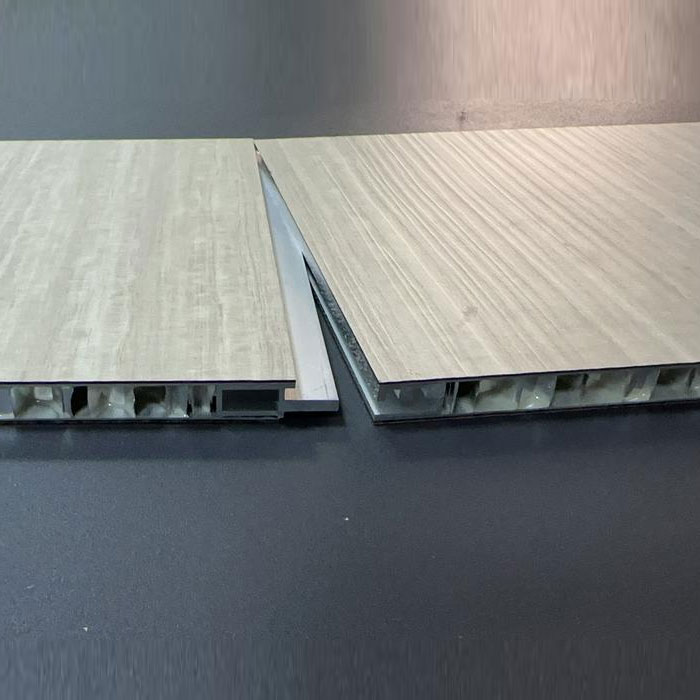

| Surface | mill finish, anodized, PVDF, stone pattern ,wood pattern, powder coating | |

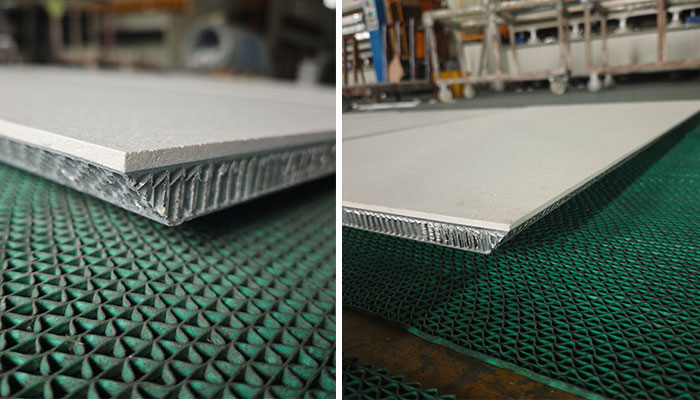

| Edge closure | open / close / epoxy edge fill / profiles connection / press-brake bend | |

| Shape | as required | |

| Application | Exterior and interior wall cladding Kitchen cabinet Tabletop Partition | |

Advantages of honeycomb panels

Customized aluminum Honeycomb have significant benefits led to the widespread application such as architectural decoration, furniture manufacturing, and transportation.

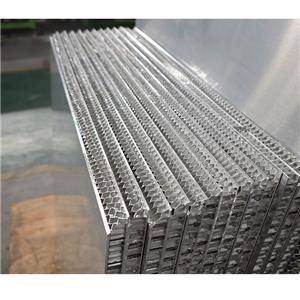

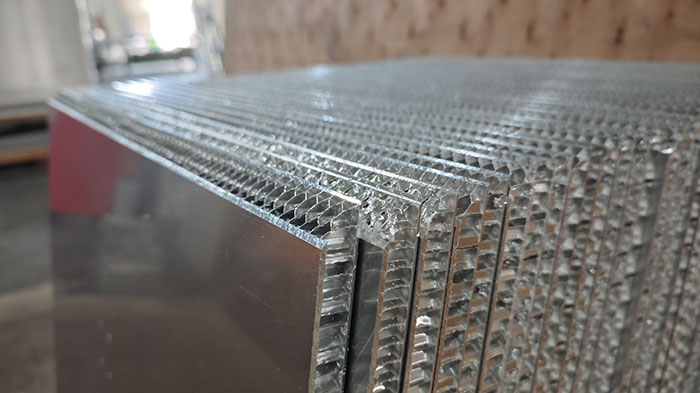

Honeycomb panels are made of two thinner panels and a thicker honeycomb core material, which gives them the characteristics of lightweight and high strength. Honeycmb panels have low density but high strength, capable of withstanding significant pressure and impact loads, and are not easily deformed.

The honeycomb structure of the honeycomb panel consists of enclosed compartments filled with air, which gives it excellent sound and heat insulation performance. Honeycomb panels can effectively block sound waves and heat transfer, improving the energy efficiency and comfort of buildings.

Honeycomb panels are made of inorganic materials or aluminum alloys with fire resistance, which have good fire resistance. In a fire, honeycomb panels can maintain structural integrity.

Honeycomb panels are all made of aluminum alloy, and can be 100% recycled. Honeycomb panels do not contain harmful substances to the human body, which is in line with modern environmental trends.

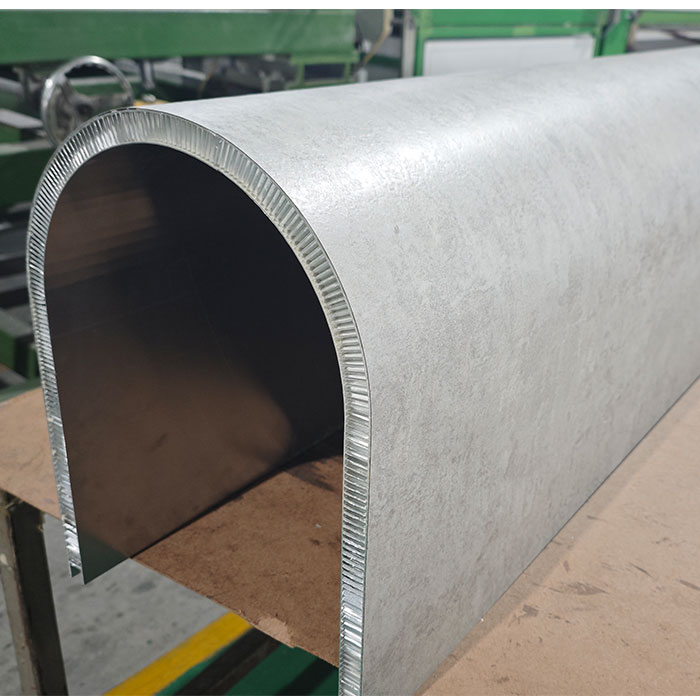

Honeycomb panels can be processed by cutting, bending, and forming as needed to meet various complex architectural and furniture design requirements. Honeycomb panels are lightweight, easy to transport and install, and reduce construction costs.

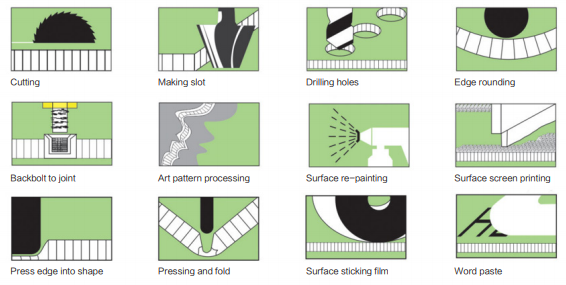

What are the process methods for aluminum honeycomb panels ?

The processing technology of honeycomb panels varies depending on the material and application field, such as cutting, stamping, bending, welding, surface treatment and assembly.