The processing details of stone honeycomb panels

Stone honeycomb panels are popular building material as the unique properties and versatility. The panels are lightweight, yet incredibly durable and strong, making them ideal for a variety of applications,like exterior and interior wall cladding, furniture, marine, table top and so on.

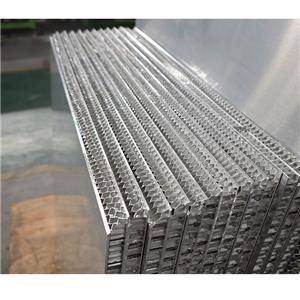

Stone honeycomb panel is made by thin natural stone composited with aluminum honeycomb panel or fiberglass honeycomb panel., but the production process of stone honeycomb panels is a complex and highly technical.

Material Selection and Preparation

Natural stone : slabs of natural stone like granite, marble, limestone,and thickness is from 3-20 mm.

Aluminum honeycomb: lightweight strength and fire resistance.

Adhesive : A high-strength epoxy adhesive

Processing and Finishing

Trimming and Cutting: After the composite has cured, panels are trimmed to precise dimensions using a waterjet cutter or CNC machine to achieve clean edges.

Edge Treatment: Depending on design requirements, the edges of the panels can be polished,honed, beveled,bush-hammered etc.

Surface Treatment: Stone surfaces may receive additional treatments such as polishing, honing, or sandblasting to achieve the desired visual effect.

Additional Considerations:

Panel Size: Stone honeycomb panels can be manufactured in large sizes due to their lightweight nature, offering greater design flexibility for walls, facades, or cladding applications.

Customization:

The stone selection, core type, cell size, and finishing options can be customized to meet specific project needs and aesthetics.