Advantages of using honeycomb panels for vacuum table

Honeycomb panel vacuum table is widely used auxiliary processing tool that can effectively improve processing efficiency and processing accuracy,such used in CNC processing, laser cutting, 3D printing, electronics industry, packaging industry and other fields.

Honeycomb panels in vacuum tables have the following advantages:

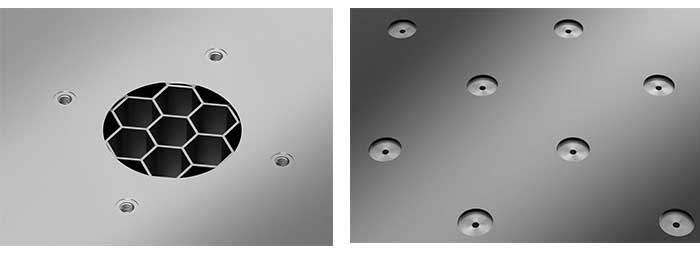

Great suction

The structure of the honeycomb panel can evenly distribute vacuum force, thereby generating strong suction, firmly fixing workpieces of various sizes and materials.

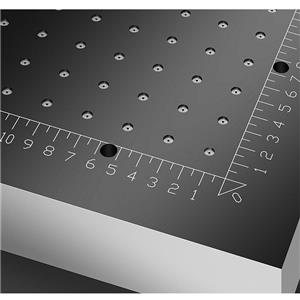

Good flatness

Honeycomb panels have a maximum board size of 2100x3950mm,with excellent flatness and deflection of 10-20 wires, which can make the workpiece fit flatly on the platform.

Good air permeability

The honeycomb structure of the honeycomb panel has good air permeability. The debris and dust generated during the processing can be discharged through the honeycomb pores in time, keeping the work surface clean, reducing dust flying, and improving the safety of the working environment. safety.

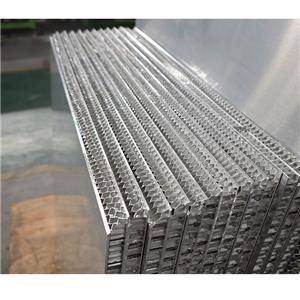

Lightweight and durable

Honeycomb panels are usually made of aluminum alloy, which has the characteristics of light weight, high strength, good durability, easy to handle and install, and long service life.