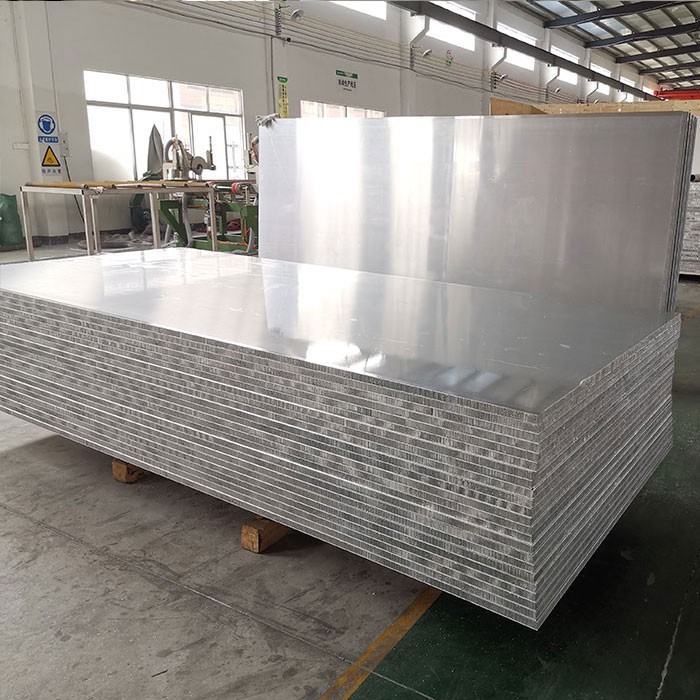

Mill Finished Aluminum Honeycomb Sandwich Panels

- Huarui

- Foshan,Guangdong

- 5-15days

- 1500㎡/day

● Honeycomb sandwich panel

● Lightweight, fireproof, waterproof

● For composite veneer

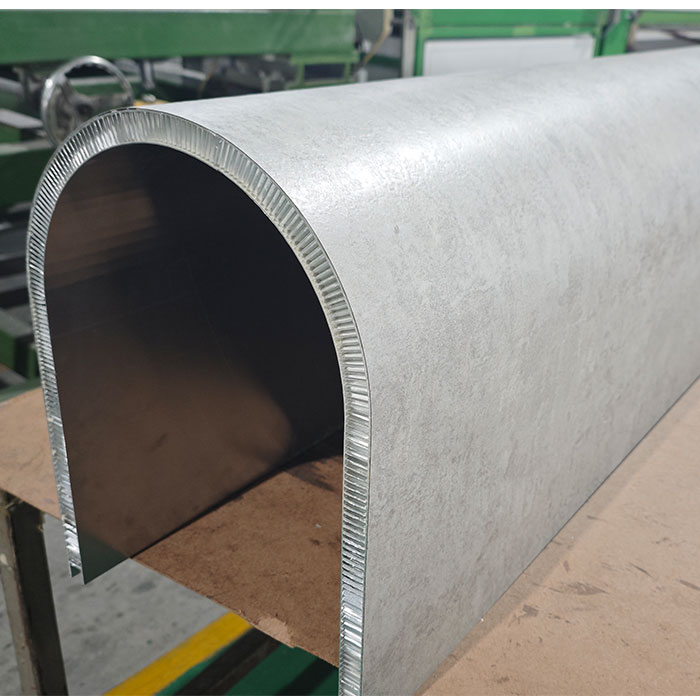

● For internal floating roof

What is mill finished aluminum honeycomb panel?

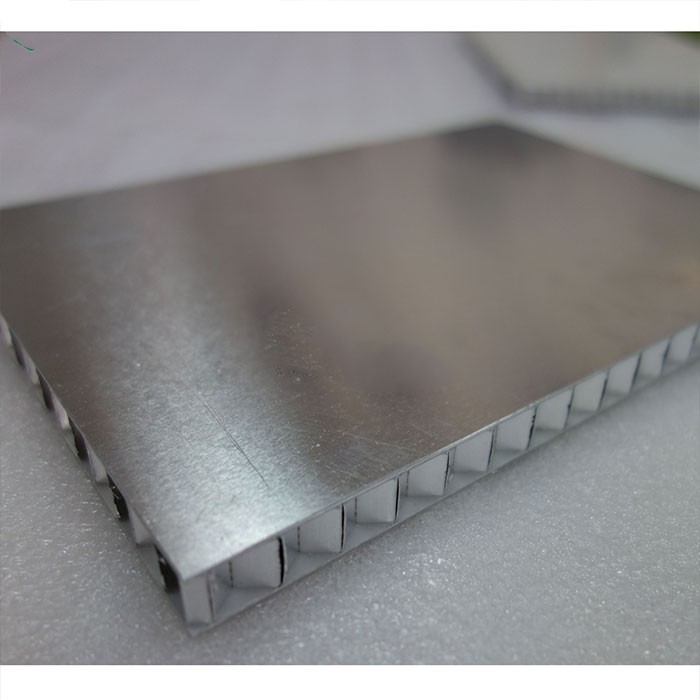

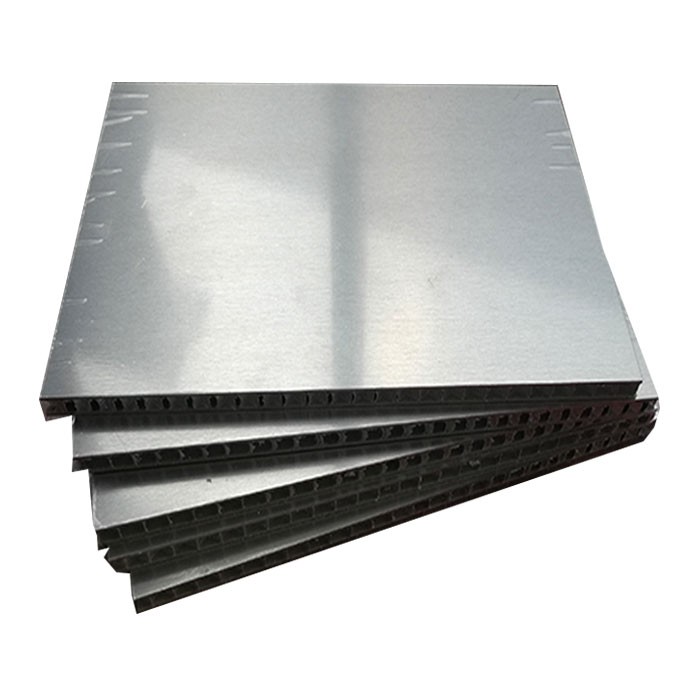

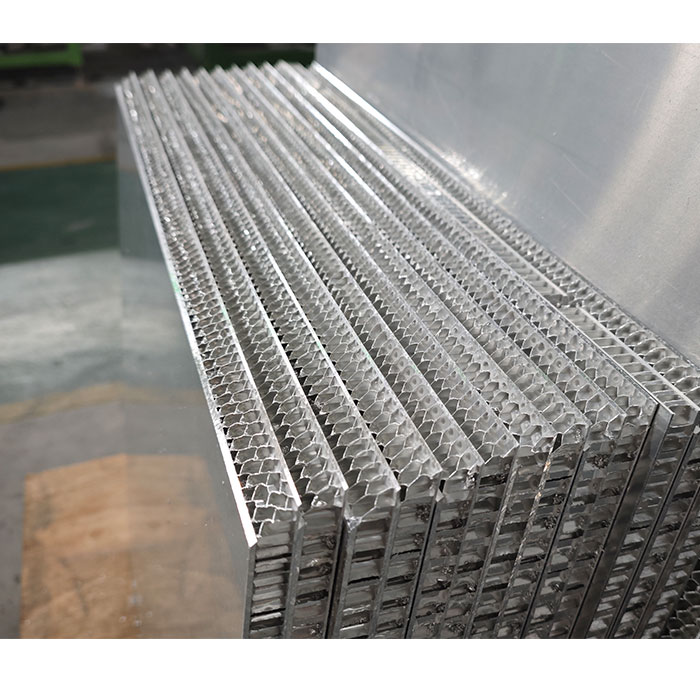

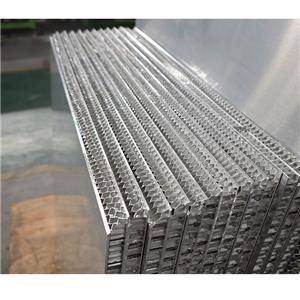

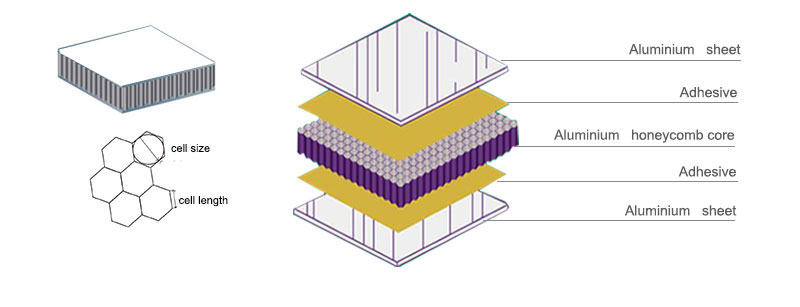

Typically 5 layers: aluminum sheet+adhesive+aluminum honeycomb core +adhesive+aluminum sheet

Mill finish aluminum honeycomb panel is of the original finish of aluminum sheet laminated with honeycomb structure.The unique honeycomb structure contributes to the panel of supper flatness sound insulation, light weight and high strength, etc.

Skin sheet | aluminum sheet AA3000,AA5000 | |

Core | aluminum honeycomb AA3003H18, AA5052H18 | |

| Adhesive | Standard glue | working temperature -40 ℃ to 117 ℃ |

High temperature glue | -40 ℃ to 180 ℃ / -40 ℃ to 200 ℃ | |

| Specification | Standard size | 1200x2500mm, 1500x3500mm |

| Standard thickness | 6mm, 10mm, 15mm, 20mm 25mm | |

Max size | 1600x 12000mm, 2500x6000mm | |

Min/Max thicknes | 3mm/ 500mm | |

Feature

lightweight |

high strength |

easy to install |

fireproof |

sound proof |

energy saving |

cost reduced |

Application

As its lightweight and high strength,mill finished aluminum honeycomb panels are mainly used as substrated panel and internal floating roof.

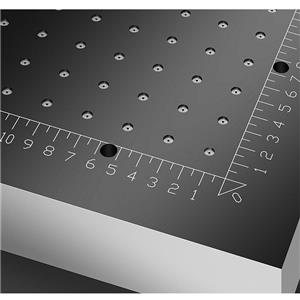

Substrate panel

It will be further processed and laminated with defferent material as composite to meet customer requirement,like stone veneer,thin porcelain,hpl,and other thin but flexible material.

Production process