FRP Fiberglass Honeycomb Sandwich Panels Supplier

- Huarui

- Foshan,Guangdong

- 5-15days

- 1500㎡/day

● Light weight,high strength,good rigidity

● Often used in logistics transportation, shelter, human body protection and other fields.

FRP Fiberglass Honeycomb Sandwich Panels Supplier

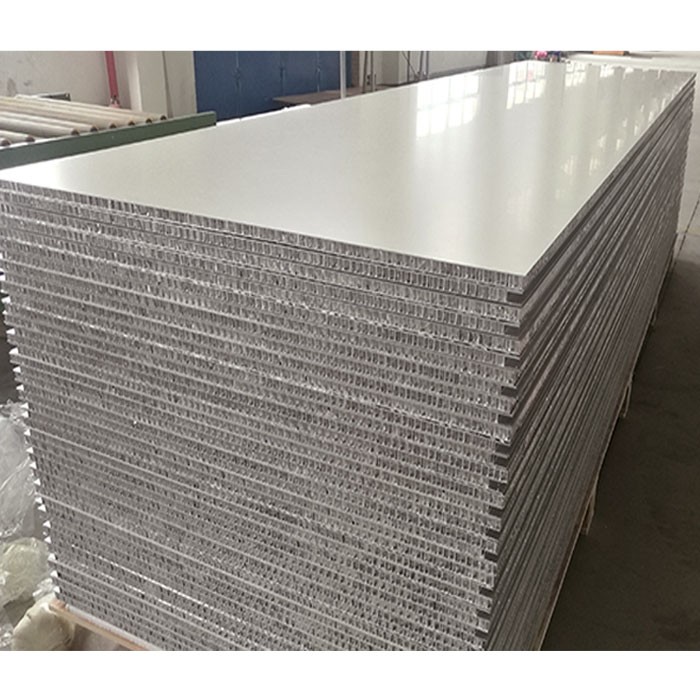

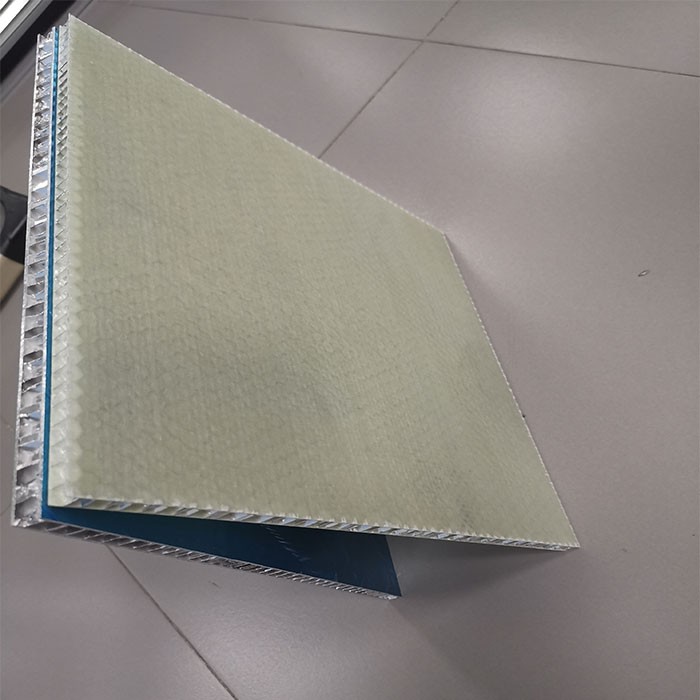

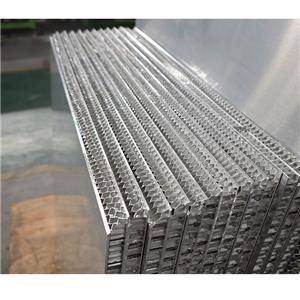

Fiberglass Reinforced Plastic (FRP) honeycomb panel is made of fiberglass skins impregnated with epoxy resin and aluminum honeycomb core between.

FRP-Alu honeycomb sandwich panels offer high mechanical performance,good impact strength,flame retardant and low maintenance cost.They have excellent application performance in logistics transportation, shelter, building decoration, air diversion and other fields.

| Face sheet | 0.5-1 mm fiberglass impregnated with epoxy resin | |

| Honeycomb core | aluminum honeycomb AA3003H18, AA5052H18 | |

| Adhesive | epoxy resin | |

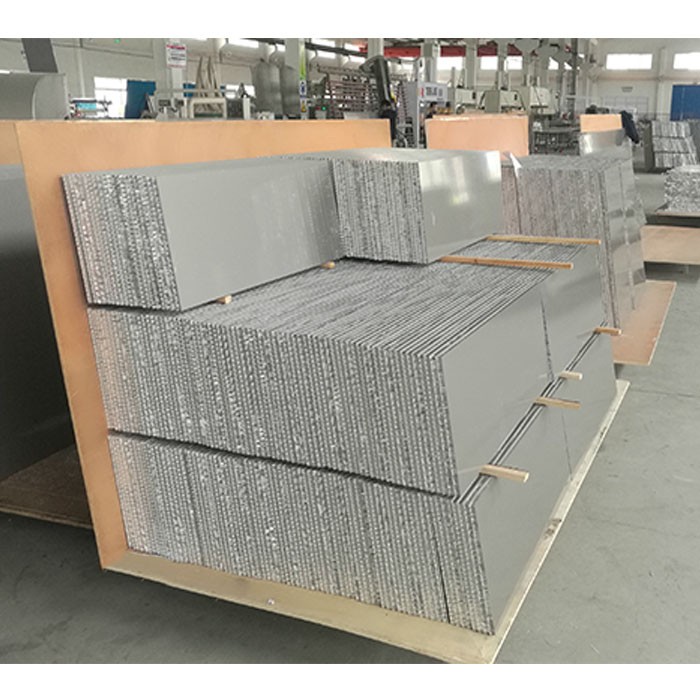

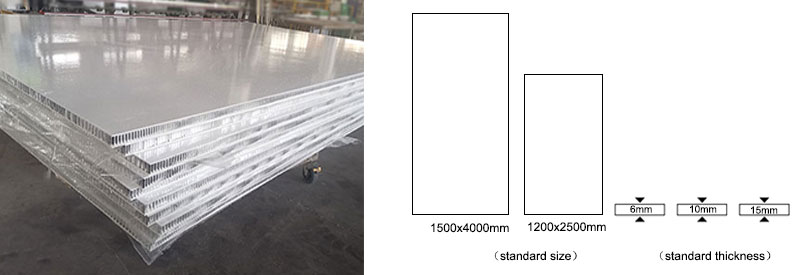

| Specification | Standard size | 1200x2500mm,1500x4000mm |

| standard thickness | 6mm,10mm,15mm,20mm,25mm | |

| Technical Propertles | fiberglass type | unsaturation resin base |

| modulus of elastlcity [N/m㎡] | 70'000 | |

| tensile strength of cover sheets [N/m㎡] | Rm≥220 | |

| 0.2% proof stress [N/m㎡] | Rp02≥130 | |

| elongation | A50≥8% | |

| linear thermal expansion | 1.2 mm/m at 100℃ temperature difference | |

| temperature resistance | -40℃ to+90℃ | |

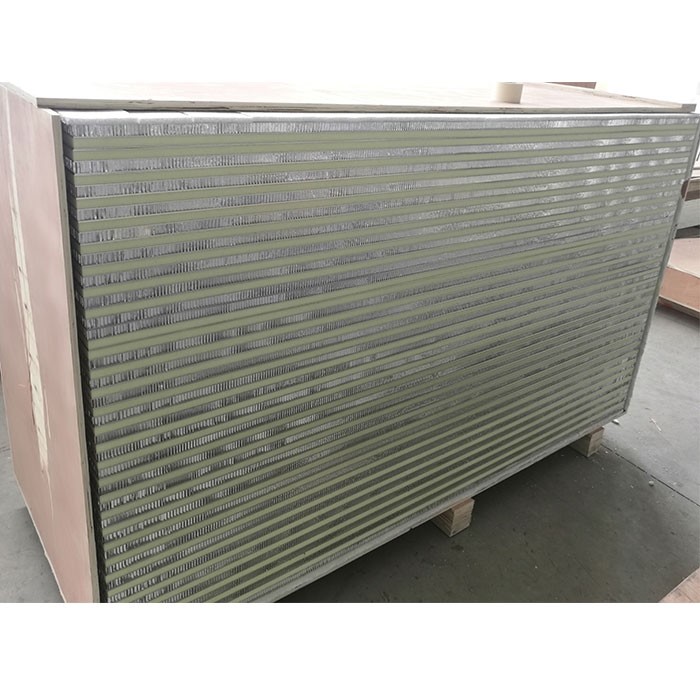

Huarui honeycomb provide range of product size,colors and finish to meet the requirement of application.In some applcaitons ,FRP honeycomb sandwich panel is also mainly used as substrate panels to composite other materials,like stone veneer,and porcelain.

| Finishing | Feature | Application | |

| Gel coat |  | Anti-UV Easy to clean High mechanical performance High weathering protection | Automative truck body trailer tri-folding hard truck logistics express vans mobile buildings refrigerated trucks cold storage panels Decorative construction cooling tower storage warehouse hospitals restaurants Marine/yacht floor partition |

| Anti-slip |  | Anti-slip Abrasion resistant Good impact strength | |

| Rough |  | Flame retardant Low maintenance cost | |