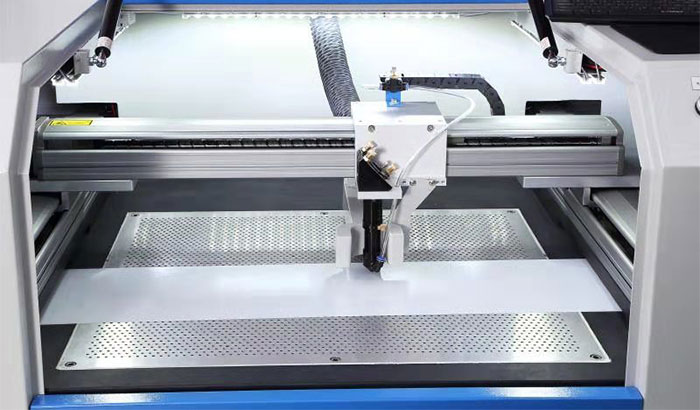

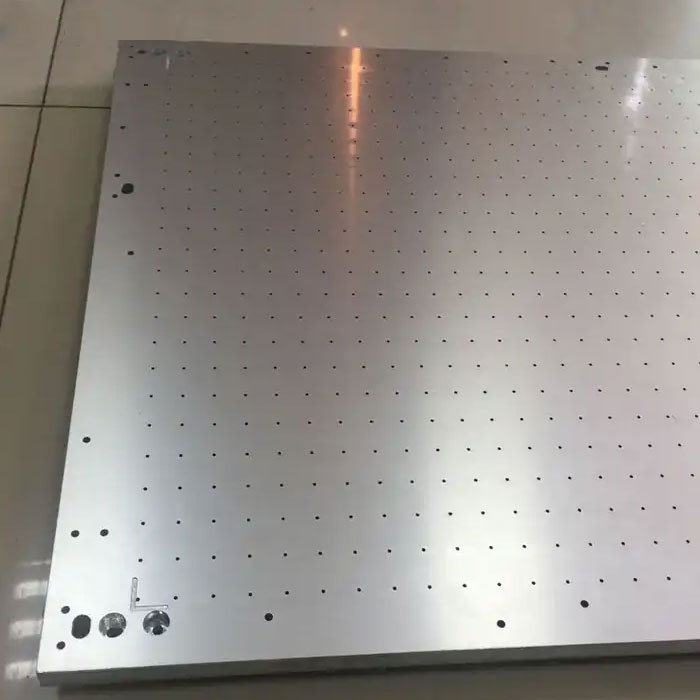

Cutting machine adsorption platform honeycomb vacuum suction table

● offers exceptional stability, versatility, and precision

● Commonly used in high-precision machining industries

Description

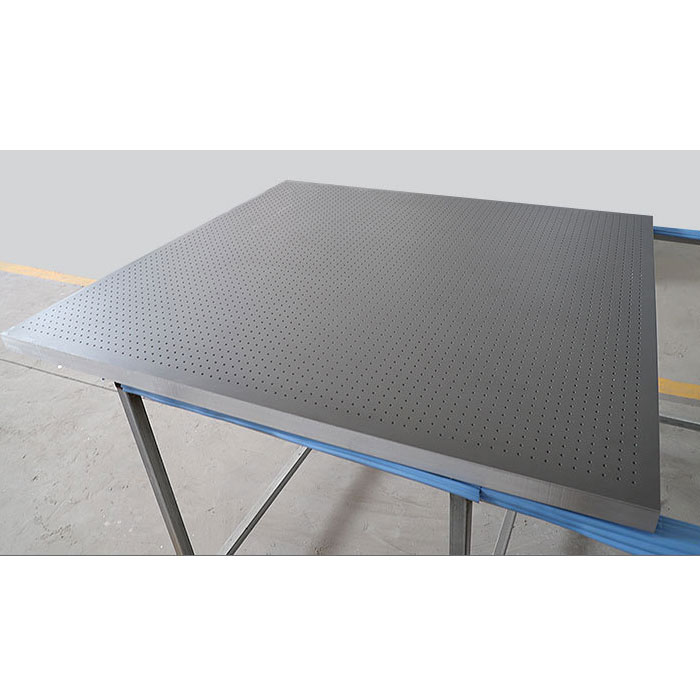

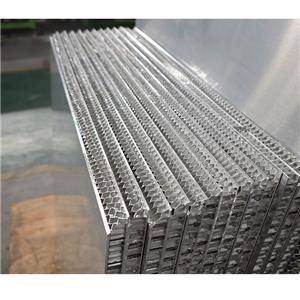

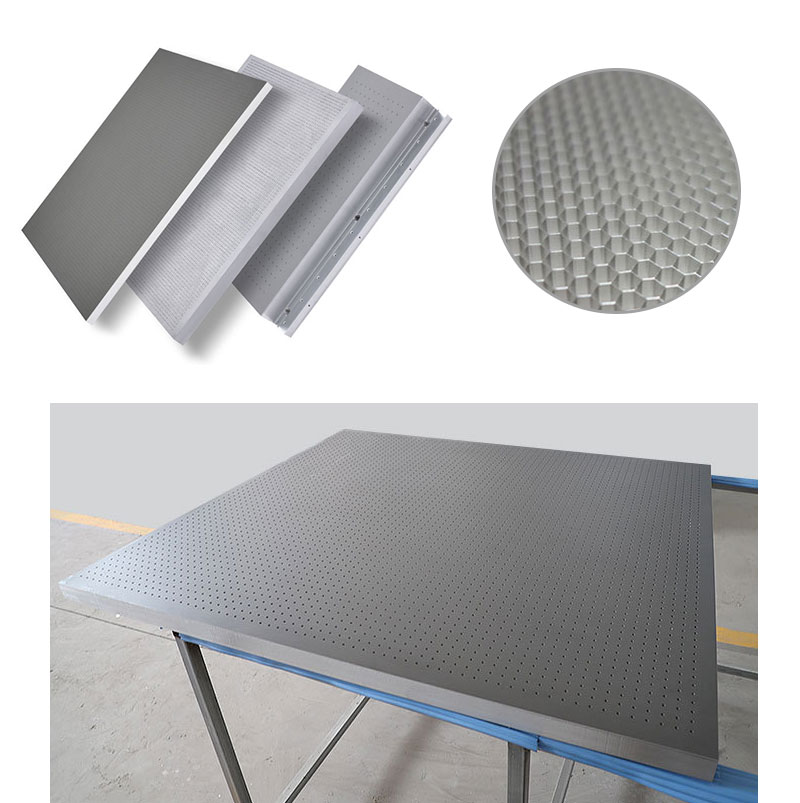

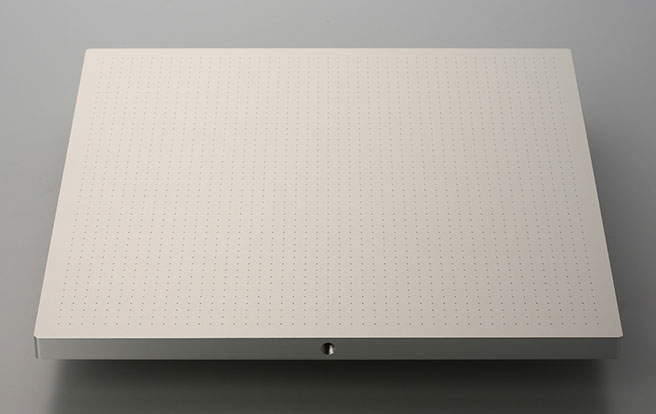

Vacuum suction table with honeycomb core offers exceptional stability, versatility, and precision.The unique honeycomb core design ensures even suction across the entire surface, resulting in reduced vibration and improved accuracy. This makes it an essential tool for manufacturing industries where precision and quality are paramount.

Feature

-Honeycomb structure, light weight and high strenght

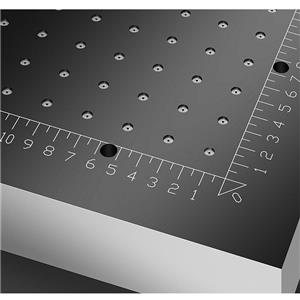

-Uniform suction and improved accuracy

-Outstanding planarity

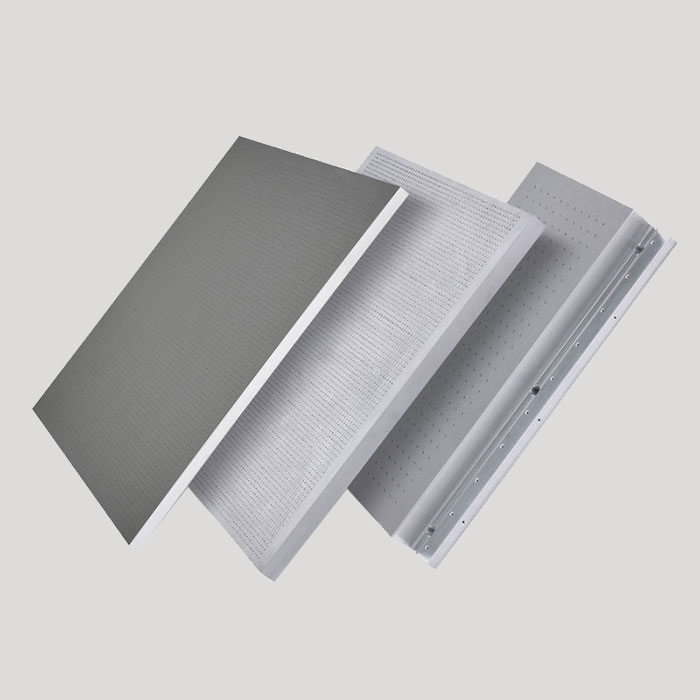

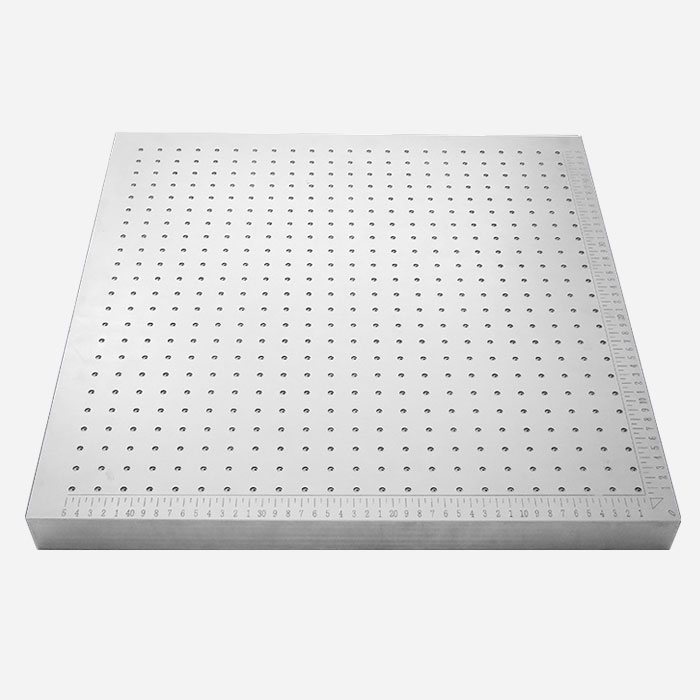

-Customized size and shape on request

Vacuum suction table can be customized according to the request of customers.

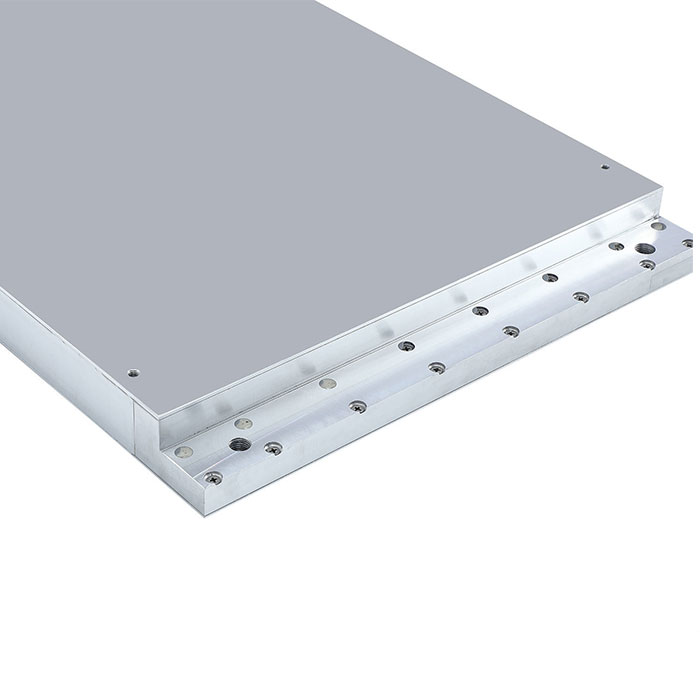

| Max size | 4000x2100mm | Thickness | 25mm , 35.5mm , 42.5mm , 53.5mm |

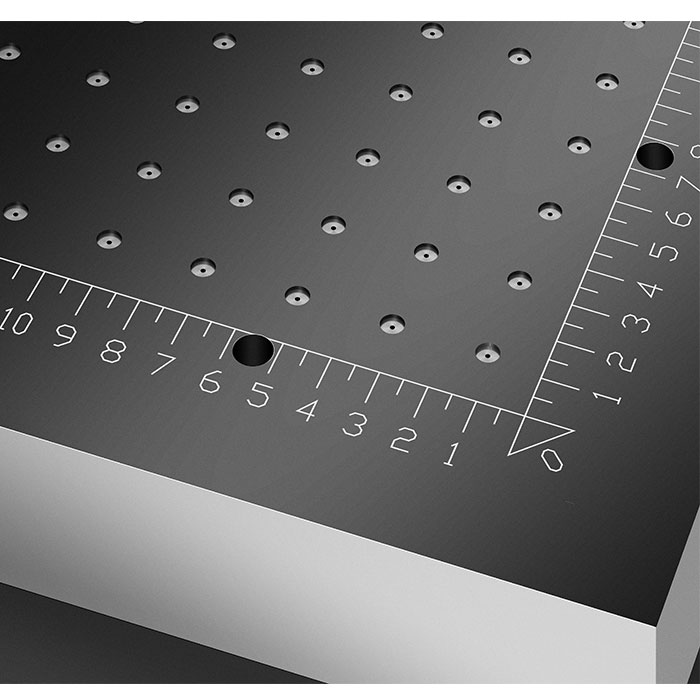

| Section hole | 1mm , 1.5mm , 2mm | Section hole spacing | 15mm , 20 mm |

| Panel material | Alloyed aluminum | Interface mode | flange , screw |

| Top sheet thickness | 2 mm | Botton sheet thickness | 2mm , 3mm |

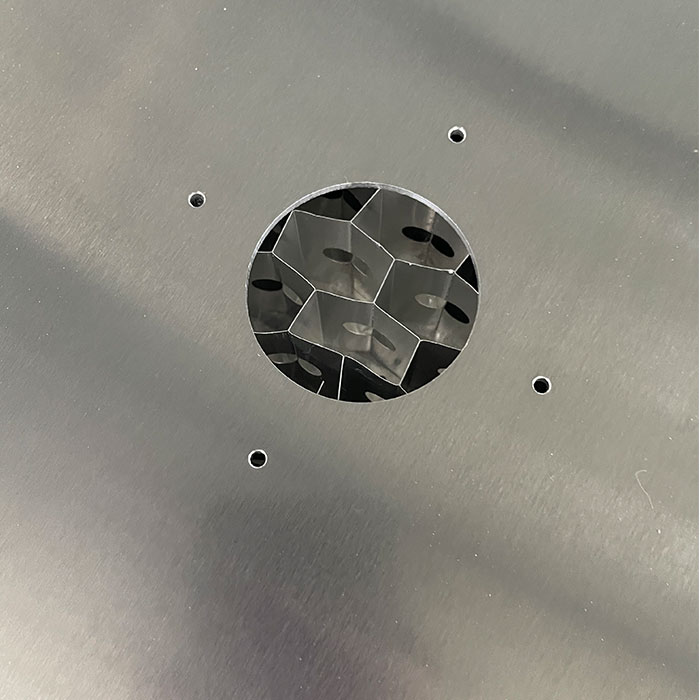

| Airentry | Φ 30 , Φ 40 , Φ 50 | Flatness | < 0.20 |

| Surface finishing | Hard oxidation,mill finish, fluorocarbon coating | Honeycomb core | cross drilled |

Application

Vacuum suction table with honeycomb core is suitable for a wide range of industrial applications, including wood, plastic, composite, aluminium and steel processing. This flexibility provides manufacturers with the capability to handle different types of materials, all while maintaining the highest level of accuracy and quality.

Vacuum suction table can be used include aerospace, automotive, marine, and renewable energy industries. It is also used in the production of furniture and cabinets.