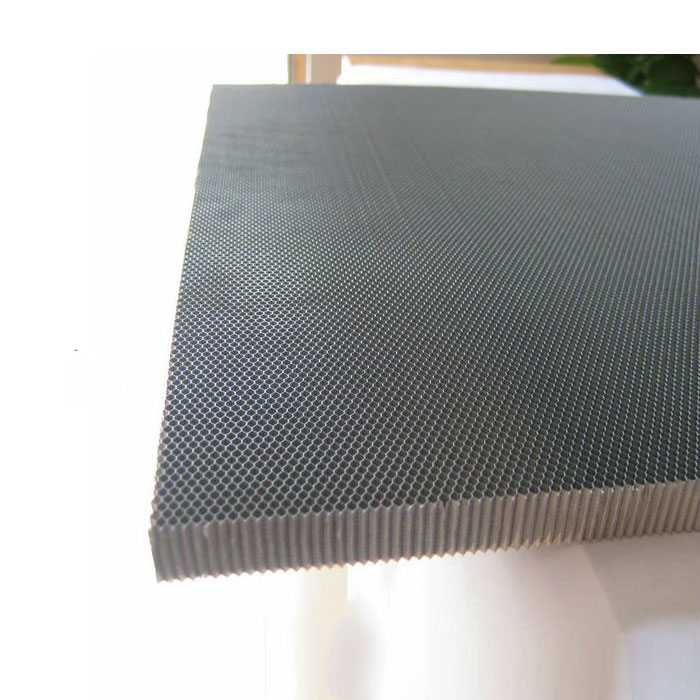

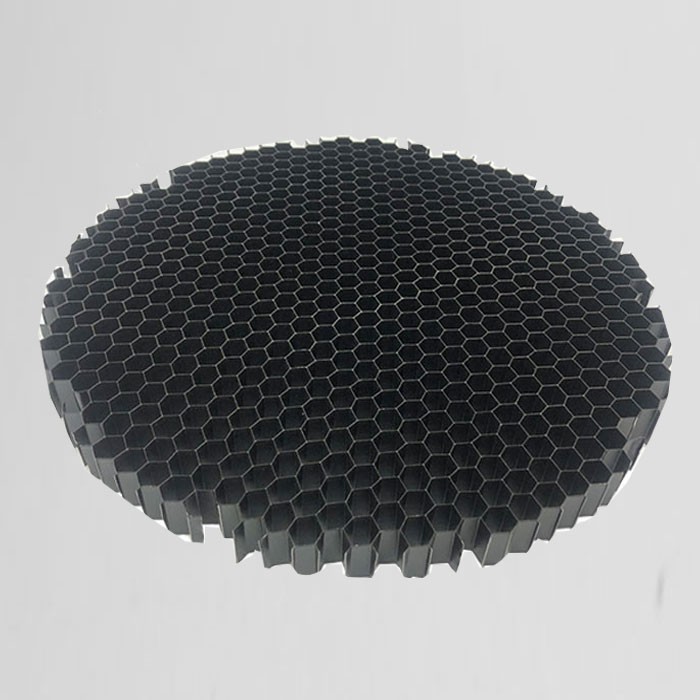

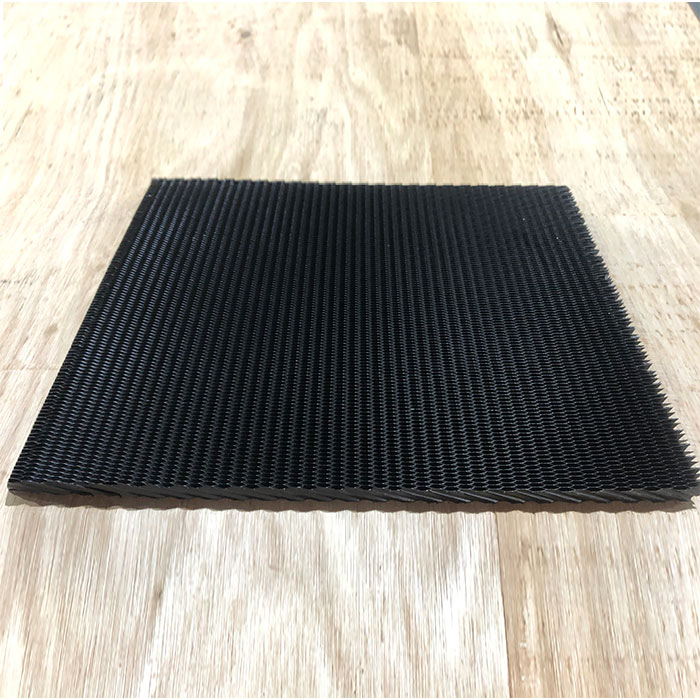

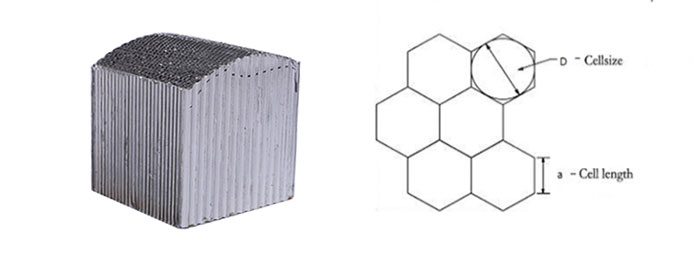

Aluminum honeycomb energy absorbers

- Huarui

- Foshan,Guangdong

- 5-15days

● Energy absorption material

● Used in high-speed trains,airplanes,spacecraft etc.

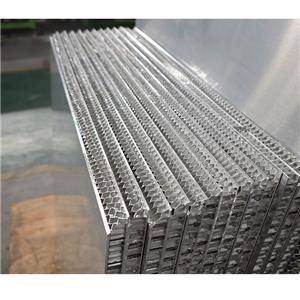

Aluminum honeycomb are provided a predictable load that can be modified by the use of various alloys,foil thickness,and cellsizes.Huarui produce aluminum honeycomb in a variety of applications.In the application of cushioning and energy-absorbing properties,it is mainly used the different-surface cushioning and energy-absorbing properties of aluminum honeycomb, which shows good compression irreversibility, high efficiency and good stability.

| Sample specification and testing result | ||||

Aluminum alloy | Cellsize | Foil thickness | Compressive strength | Crush strength |

| 5052H18 | 1/16" | 0.04 mm | 6.38 Mpa | 3.92 Mpa |

| 5052H18 | 1/10" | 0.06 mm | 9.98 Mpa | 4.82 Mpa |

| 5052H18 | 1/8" | 0.06 mm | 5.48 Mpa | 3.25 Mpa |

| 3003H18 | 1/10" | 0.06 mm | 9.04 Mpa | 3.95 Mpa |

Aluminum honeycomb, as a buffer and energy absorption material,has been widely used in high-tech fields such as vehicle impact barriers,lighweight body armour,train buffers,elevator or lift protection,dummy neck calibration etc.

Vehicle impact test

Aluminum honeycomb can help absorb the energy of impact during the automobile collision and vibration reduction process.

Dummy neck calibration

Aluminum Honeycomb energy absorbers are used to create the pulse for neck flexion extension tests for ATD's certification.

Transportation

The lightweight and high strength aluminum honeycomb play important role in the safety of automotive and rail industry.