Marine Decoration Material-HPL Honeycomb Panel

Compared with traditional metal structural materials, the new composite material has a higher strength/mass ratio. The use of new composite materials not only changes the interior design style, but also reduces carbon emissions, improves ship safety performance, and increases living comfort.

The application research of ship interior materials in cabin space should take into account the four characteristics of decorative materials: energy saving and environmental protection, fire and heat insulation, noise reduction and sound insulation, and lightweight materials.

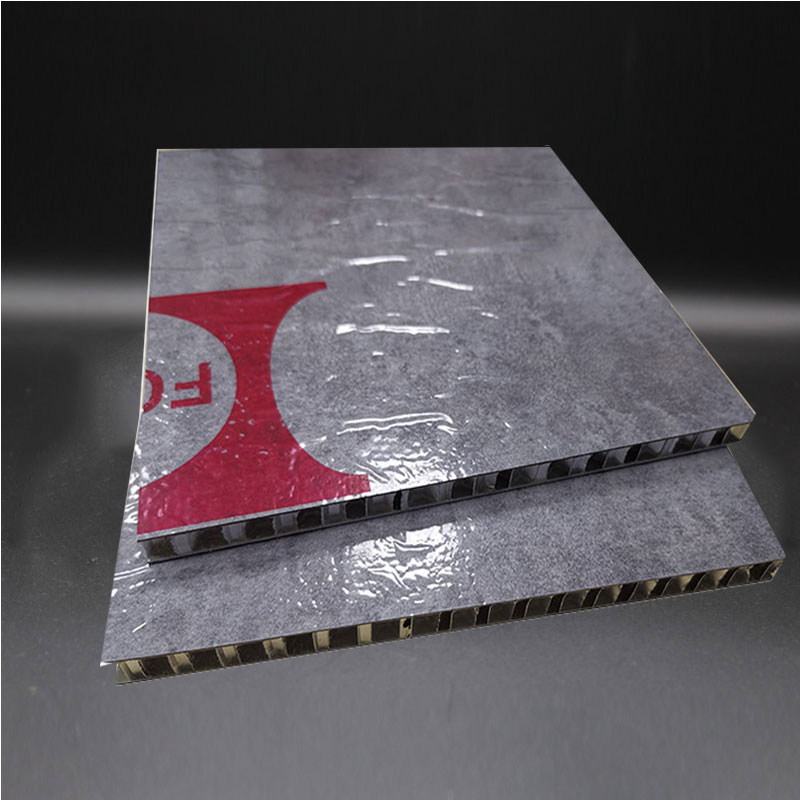

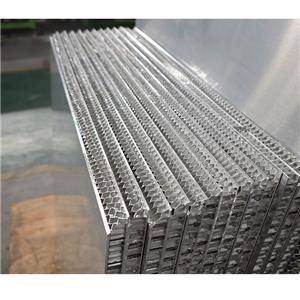

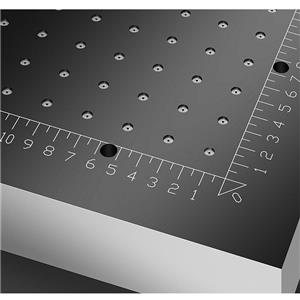

Aluminum honeycomb sandwich structure composite materials are light in weight, high in strength and rigid, and are mostly used as structural parts with large structural dimensions and high strength requirements. High-end ships often use aluminum honeycomb panels as processing materials for panels. Its fireproof, corrosion-resistant, environmentally friendly, and easy to dismantle and assemble characteristics have become an excellent design material in the interior design of luxury ships.

Aluminum honeycomb panels can be used to manufacture ship interior panels such as control panels, bulkheads, ceiling pads, luggage racks, toilet units, toilets, bottom panels, four-corner doors and isolation doors, as well as external components such as roofs, high-ends, guard plates, The whole car body, car board, etc.