Introduction of high pressure laminate

High pressure laminate is a refractory building material for surface decoration.It is available with special performance properties including chemical, fire and wear resistance. The production technology allows obtaining different options for the surface finishing - glossy, matte, structural. The high-pressure laminate sheets can be decorated from one or two sides.

There are many types or grades of high pressure laminates engineered for specific performance requirements.

General HPL: Most widely used HPL and suitable for horizontal and vertical surface applications. The thickness of the finished products varies in the range from 0.5mm to 25 mm.

Postform HPL: It can be formed around curved edges by application of heat and restraint.

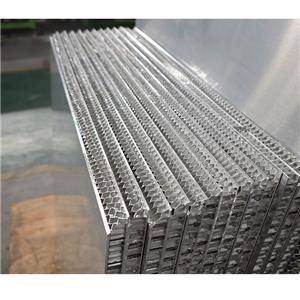

Aluminum backing HPL

CPl (Continuous Pressure Laminate))

LPL

The surface can be made as follows.

wood-grain veneer

solid veneer

metal veneer

stone veneer

This material is used for interior and exterior.It can be used in interior decoration, furniture, kitchen cabinets, laboratory countertops, and exterior walls.

Special purpose of the high pressure laminates includes cabinet liners, high-wear, fire-rated, electrostatic dissipative and chemical resistant laminates, anti fungal and anti microbe HPL for hospitals and clinics.