Marine Vessels-interior wall cladding and ceiling panels

The requirement of marine industry

Marine materials: weight reduction, corrosion resistance, strength,energy saving

Pursue: speed increase, more cargo capacity,fuel economy, low maintenance, recyclability

Huarui honeycomb supply high strength-to-weight ratio aluminum honeycomb products, an ideal for all areas of marine vessels, providing solutions from stem to stern.We have certain qualifications as follow:

| Wheelmark certification Aluminium honeycomb is suitable for use on board European marine vessel. |

| Fire protection Certified with Non-combustibility test(EN ISO1182) |

| under IMO MED Module B+D | |

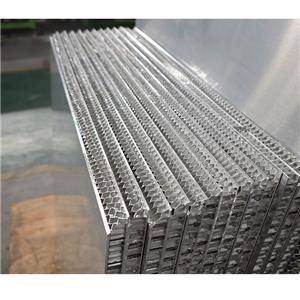

Feature of aluminum honeycomb panels

Corrosion resistance

Energy saving,to lightweight means more cargo capacity,fuel economy

Weight saving: to reduce the weight of the components without compromising their mechanical features

Based on the project, there are endless options of honeycomb materials, construction, finishes and fabrication to give you a strong, lightweight product,like HPL / PVC / stainless steel/ mill finished aluminum honeycomb panels.

HPL skin aluminum honeycomb panel |

PVC veneer aluminum honeycomb panels |

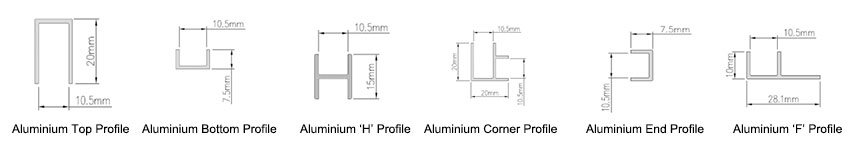

We also provide some connection for the installation of honeycomb panels,like exposed triming,invisible profile,and seamless connections.Here are some profile sample for the installation.

Application

Aluminum honeycomb panels can be used to manufacture ship interior panels such as control panels, bulkheads, ceiling pads, luggage racks, toilet units, toilets, bottom panels, four-corner doors and isolation doors, as well as external components such as roofs, high-ends, guard plates, The whole car body, car board, etc.

partition wall |

water bus cruise interior |

ceiling decoration |

furniture |