Adhesives for Bonding aluminum honeycomb panels

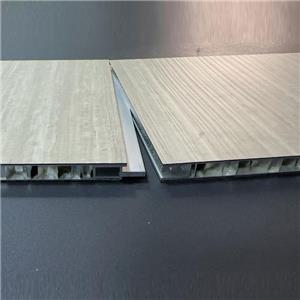

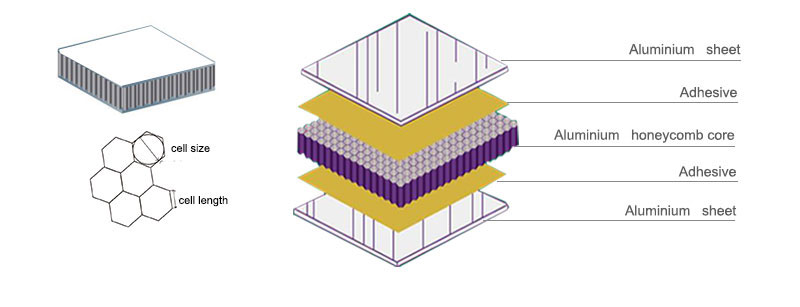

Honeycomb sandwich panels,are made of two thin face layers bonding with Aluminum honeycomb core.They are manufactured using a variety of different materials, ranging from paper, reinforced plastics, aluminium or thermoplastics (polypropylene) depending on their desired applications and specification.

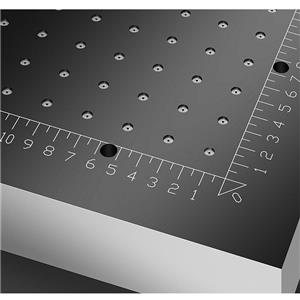

Aluminum honeycomb sandwich panels are used in many scientific and engineering applications, including automotive, aerospace, marine and sports industries.

The Significance of Adhesives in Honeycomb Panels

To prevent the two face layers outside the honeycomb core from slipping and working in opposition to one another, they must be structurally bonded to the core. When a load is applied to the panel and a bending force is present, it is the role of the adhesive to counteract that force by providing a shearing force, consequently stabilising the face layers and the whole panel. Therefore, it is essential that the adhesive used is of supreme quality and allows the shear loads to be transferred effectively.

According to different characteristics and applications of aluminum honeycomb panels, choose the appropriate bonding method.For example:

1. Produced with polyurethane and epoxy resin room temperature curing adhesives

2. Produced by epoxy film process

3. Using thermoplastic film continuous compounding process